Corundum zest Engines

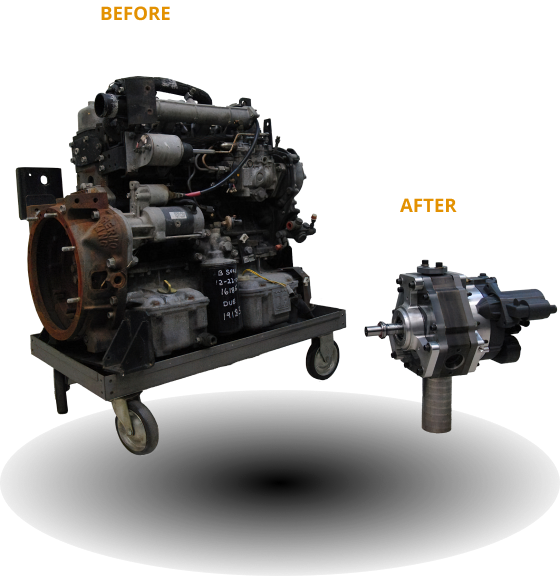

10X more power, 30% more efficient

We have significantly upgraded the Wankel rotary engine taking into account modern engineering solutions, and also increased the engine life many times by using

a heavy-duty ceramic corundum coating

a heavy-duty ceramic corundum coating

Order

About us

Contact

Small and compact like an iPhone

Features

Lightweight and compact

up to 80%

smaller and lighter

than piston diesel engines

than piston diesel engines

up to 30%

smaller and lighter

than reciprocating engines

than reciprocating engines

corundum coating

increases the engine life

by 7 times

increases the engine life

by 7 times

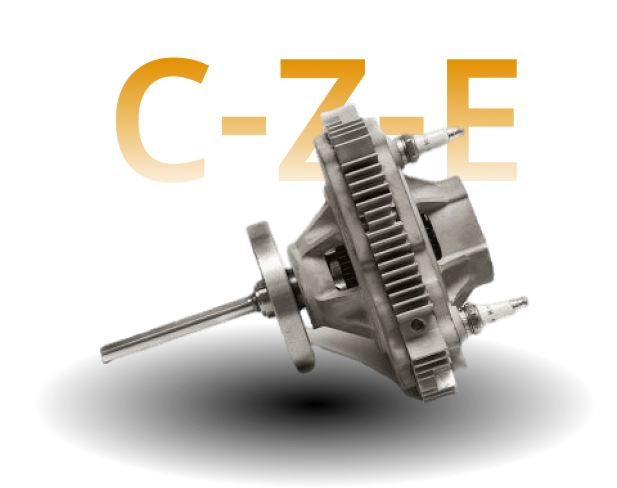

Low vibration & low maintenance

Exhaust volume is kept to a minimum by new engineering solutions. Quiet, no valves.

only two moving parts,

optimally balanced,

almost zero vibration

optimally balanced,

almost zero vibration

Ability to run on multiple fuels (spark ignition) or heavy fuel (compression ignition): Diesel, Gasoline, Natural gas, Kerosene

Technology

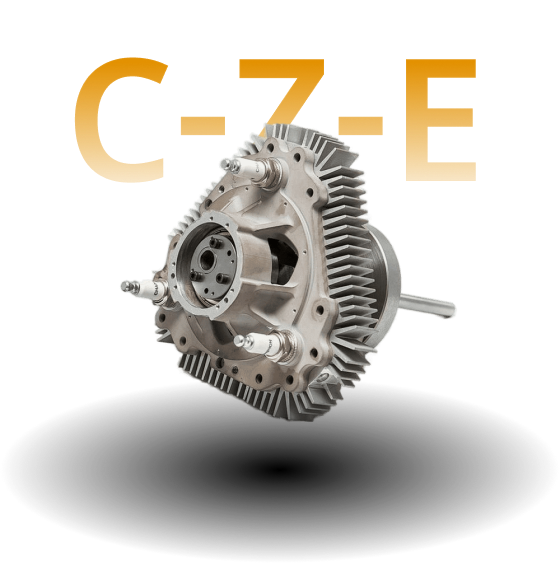

burning constant volume (adiabatic combustion)

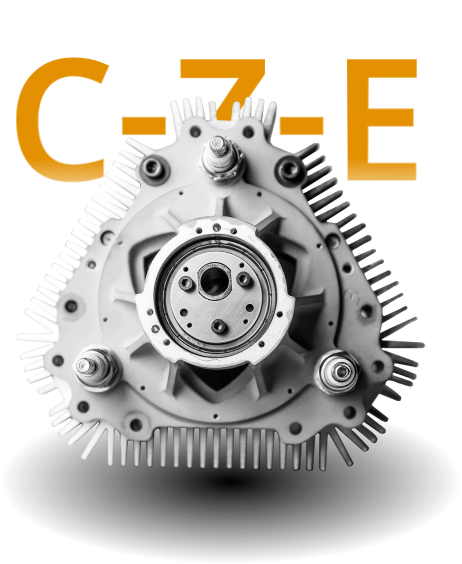

C-Z-E rotary engine is not a Wankel engine. It is designed using highly efficient thermodynamic cycle, heavy-duty,

wear resistant corundum coating

wear resistant corundum coating

Innovative technology can be considered an inverted Wankel engine. With the help of this development, problems with sealing, cooling, efficiency, and with

the reliability of the construction were solved

the reliability of the construction were solved

C-Z-E rotor, unlike Wankel, has better properties:

excessive expansion

more reliable

construction

construction

high compression

ratio

ratio

Secret of extreme reliability

The coating of pistons and other elements of the crank mechanism ensures reliable operation of the engine

for a long time, increases the power of engine & service life

for a long time, increases the power of engine & service life

In our engines, we use one of innovative technologies -

a super hard wear-resistant protective corundum coating

a super hard wear-resistant protective corundum coating

Corundum coating

We have developed a new formula for ceramic-metal coatings obtained by a method of thermal electrochemical oxidation

Turbo response is improved and engine coolant and oil

temperatures are reduced

temperatures are reduced

Indelible barrier against friction and temperature

Up to 10% reduction in fuel consumption

Increase in efficiency by 5-7%

by increasing the adiabaticity

of the combustion chamber

by increasing the adiabaticity

of the combustion chamber

Reduced wear, the ability to abandon the air filter

Increasing the power & resource of the engine

Power

Up to 5% increase in torque

No friction

Friction coefficient ≤0.010

Thermoregulation

Withstands up to 2000 °C

Elevated temperatures and high friction are factors that can damage any internal combustion engine

1000% improved wear resistance

Due to the specific mechanical, tribological and physicochemical characteristics of the corundum coating, such as strength, microhardness, friction properties, wear resistance, chemical

and thermomechanical stability, thermal conductivity,

such coatings are used in various industries

and thermomechanical stability, thermal conductivity,

such coatings are used in various industries

About company

Our group of companies was founded in 2007

in Russia (Novosibirsk) in Akademgorodok -

the largest Russian research center

in Russia (Novosibirsk) in Akademgorodok -

the largest Russian research center

We have serious experience in medicine, physics, biotechnology, nanotechnology, chemistry, mathematics, automotive and instrumentation.

Contacts

support@al2teo.com

UAE, Dubai

Silicon Oasis

SIT Tower

office 1810

+971 52 102 0256

Silicon Oasis

SIT Tower

office 1810

+971 52 102 0256

Russia, Novosibirsk

Akadempark

Nikolaev st., 11

office 406

+7 800 511 56 77

Akadempark

Nikolaev st., 11

office 406

+7 800 511 56 77

Italy, Montecchio

Maggiore

Via II giugno n.6

Maggiore

Via II giugno n.6