Corundum

Zest Engines

Zest Engines

10x MORE POWERFULL

30% MORE EFFICIENT

30% MORE EFFICIENT

SCROLL

Innovative ideas

our solution

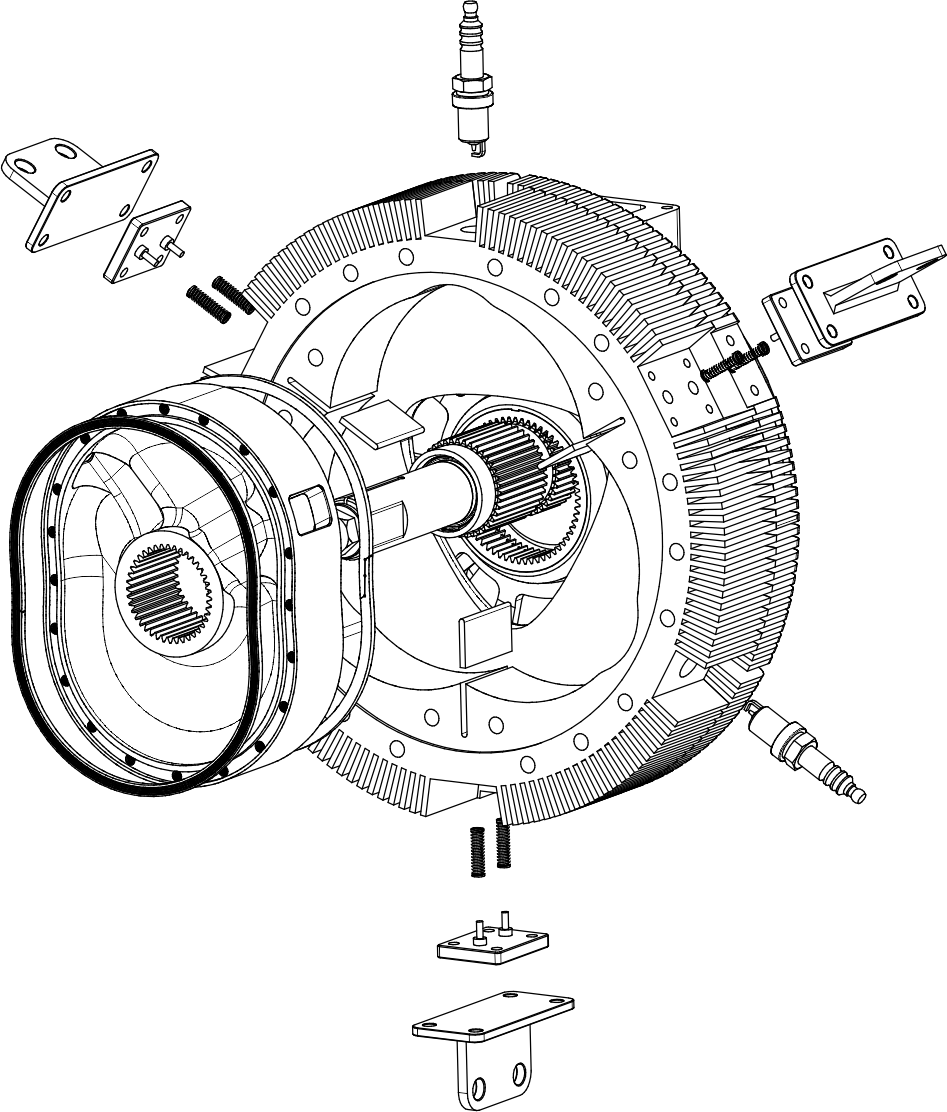

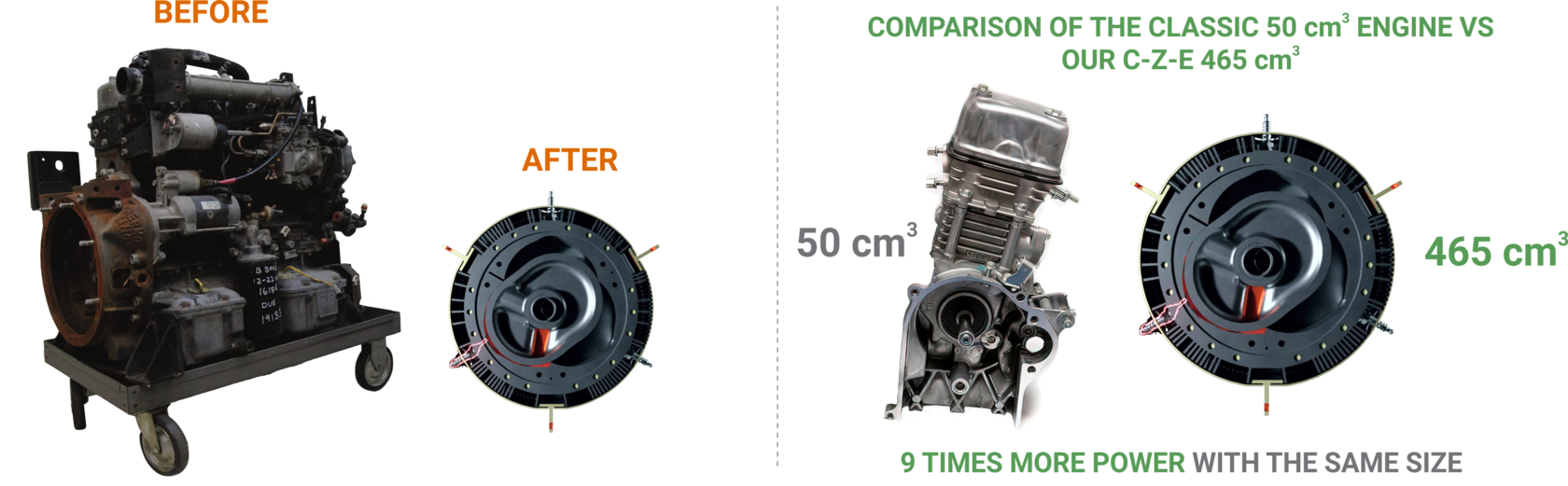

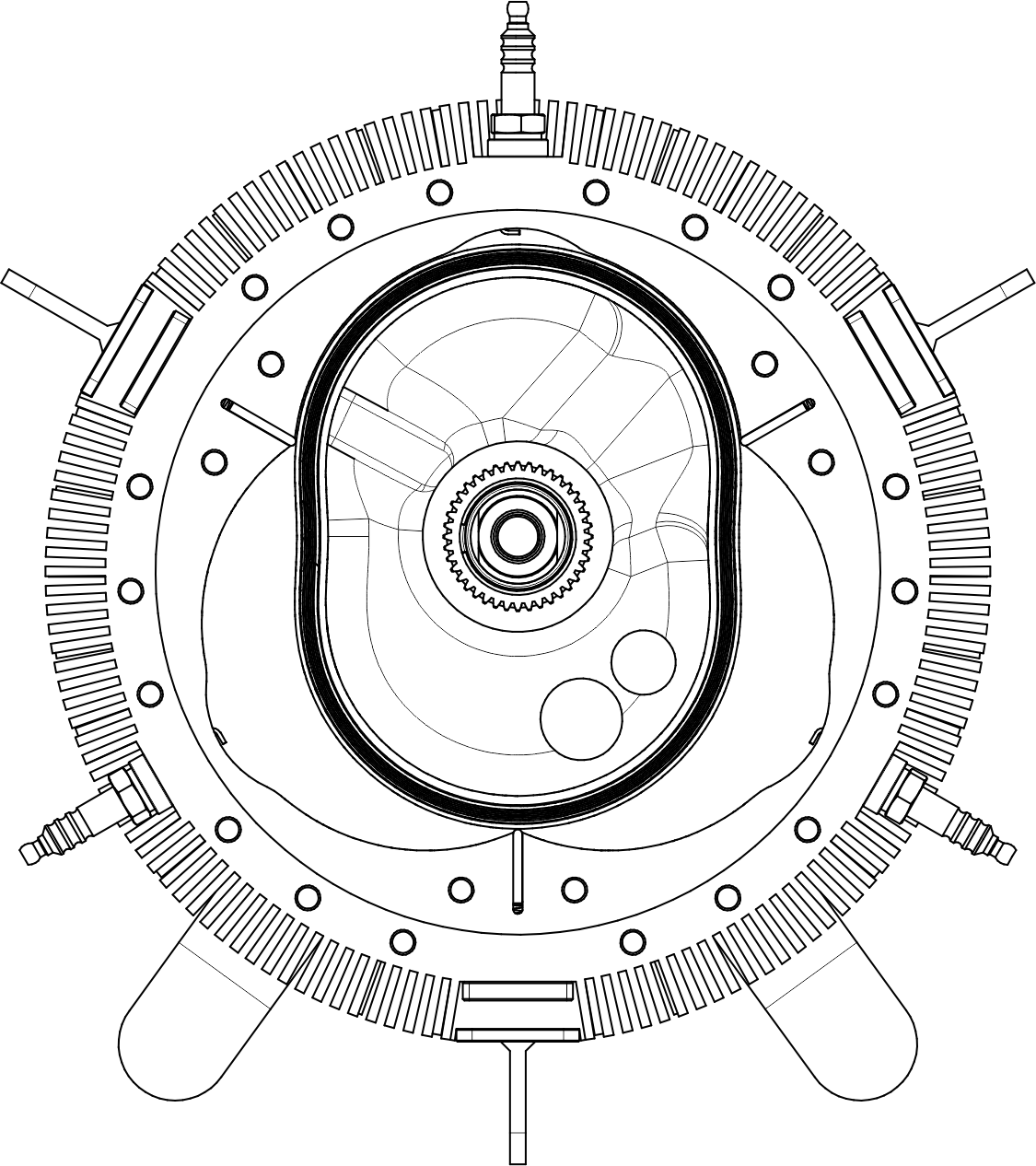

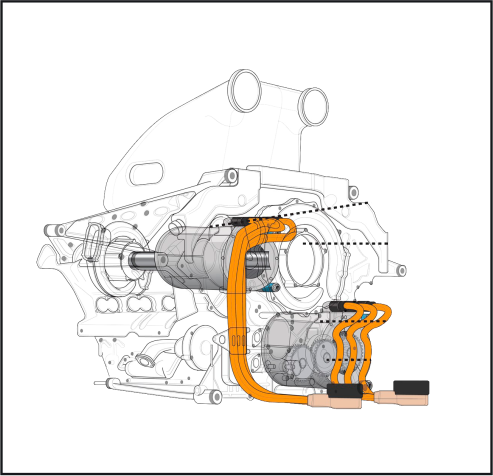

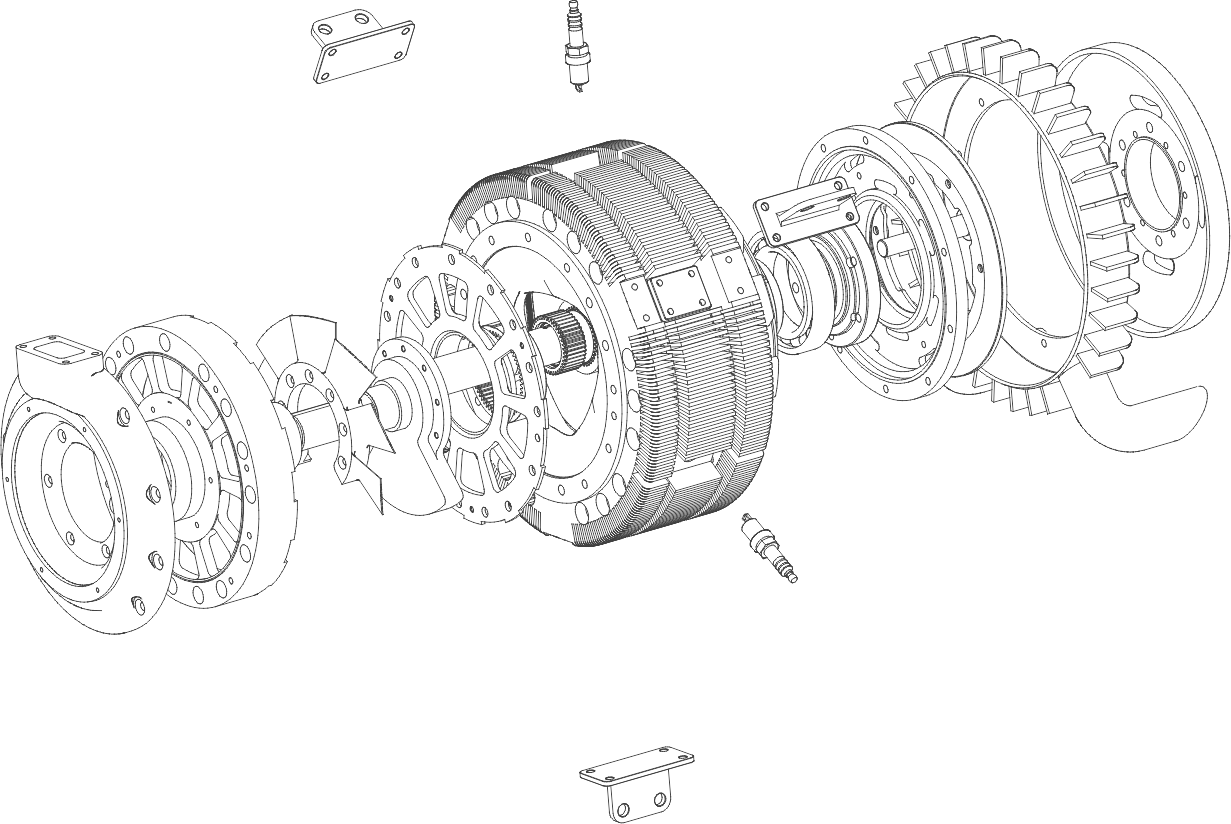

We have significantly upgraded the Wankel rotary engine taking into account modern engineering solutions, and also increased the engine life many times by using hard heavy-duty ceramic corundum coating. Exhaust volume is kept to a minimum by new engineering solutions.

Our design solution solves problems with sealing, cooling, efficiency, and reliability of the construction in any situation.

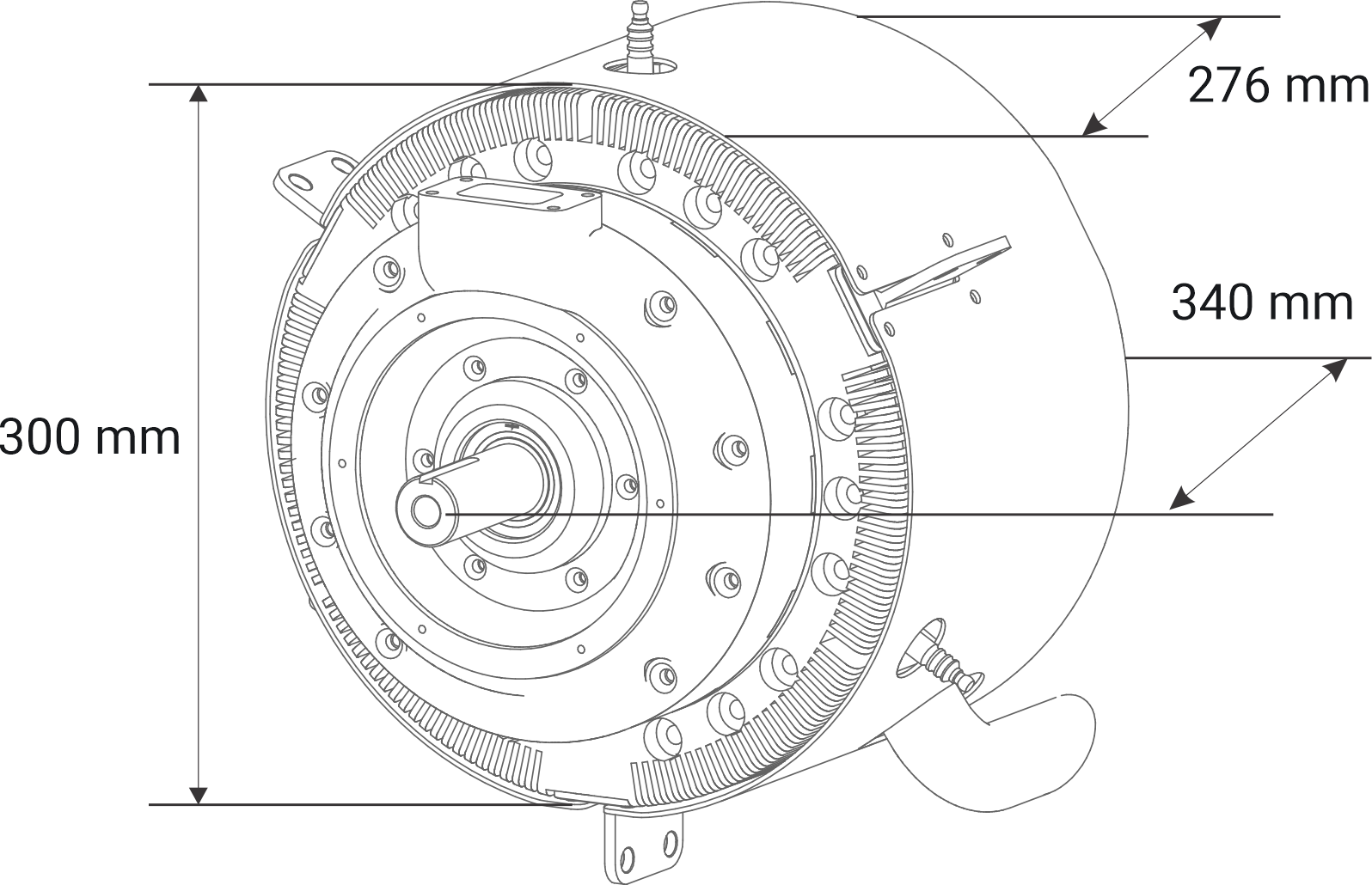

Technical characteristics of

two-stroke rotary engine:

two-stroke rotary engine:

Features

Ability to run on multiple fuels (spark ignition) or heavy fuel (compression ignition): Diesel, Gasoline, Natural gas, Kerosene

Low vibration &

low maintenance

low maintenance

- optimally balanced,

- almost zero vibration,

- only two main moving parts

+

corundum coating

- increases the engine life by 7 times

+

Lightweight &

compact

compact

- smaller and lighter than a classic internal combustion engine

+

UP TO 40%

- engine efficiency

+

UP TO 70%

TECHNOLOGY

C-Z-E rotary engine is designed using highly efficient thermodynamic cycle and heavy-duty, wear resistant corundum coating

C-Z-E ROTOR, UNLIKE WANKEL, HAS BETTER PROPERTIES:

High compression ratio

More reliable construction

Burning constant volume

(adiabatic combustion)

(adiabatic combustion)

Secret of extreme reliability - Corundum coating

We have developed a new formula for ceramic-metal coatings obtained by a special method of thermal electrochemical oxidation

+

Indelible barrier against friction and temperature

Corundum coating let engine withstand elevated temperatures and high friction, which normally damage or even destroy classical combustion engine

+

COATING THERMORSISTANCE

Withstands up to 2000 °C

Withstands up to 2000 °C

NO FRICTION

Friction coefficient ≤0.010

Friction coefficient ≤0.010

POWER

Due to the low coefficient of friction and other parameters of the AL2TEO coating, fuel consumption is reduced by 7-20%, and efficiency increases by 5-15%

Due to the low coefficient of friction and other parameters of the AL2TEO coating, fuel consumption is reduced by 7-20%, and efficiency increases by 5-15%

EXTRA HARD CORUNDUM COATING

Thermo-electrochemical oxidation -

method of layer-by-layer deposition on metals of oxide coatings with the following properties

method of layer-by-layer deposition on metals of oxide coatings with the following properties

Our patented method has a number of advantages over the technologies offered on the market:

- Maximum density at comparative cost

- Coating thickness up to 500 microns

- The possibility of covering small holes with a diameter of 4 mm

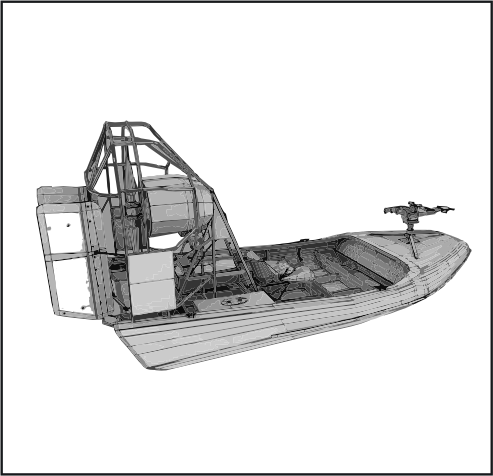

application of Corundum Zest Engines

Hybrid installation for electric vehicles

motor vehicles: motorcycles,

snowmobiles, buggies,

go-karts, paragliders

snowmobiles, buggies,

go-karts, paragliders

Light aircraft

Aerosledges,

military industry

military industry

Send an enquiry

ABOUT COMPANY

Our group of companies was founded in 2018 in Russia (Novosibirsk) in Akademgorodok - the largest Russian research center.

We have vast experience in medicine, physics, biotechnology, nanotechnology, chemistry, mathematics, automotive and instrumentation.

The company is part of three organizations working in the field of science, located across 4 continents.

- R&D office, Russia, Novosibirsk, Nikolaev street, 11

- UAE, Dubai, Silicon Oasis, SIT Tower, office 1912

- Italy, Montecchio Maggiore (VI), Via 2 Giugno 6

- China, Chengdu, 中科微电子产业技术西南研究院孵化中心

- R&D office, Russia, Novosibirsk, Nikolaev street, 11

- UAE, Dubai, Silicon Oasis, SIT Tower, office 1912

- Italy, Montecchio Maggiore (VI), Via 2 Giugno 6

- China, Chengdu, 中科微电子产业技术西南研究院孵化中心

OUR PROJECTS

Innovative protective coating for metals which has high microhardness, specific frictional properties, and retain complete resistance to external and internal factors.

INNOVATIVE HEALTH-CHECK STATION HUMAN EXHALATION CONTAINS MORE THAN 750 VOLATILE COMPOUNDS. By measuring the amount, concentration and ratio of gases released during breathing, we can make conclusions about metabolic changes and the presence of disease.

VODOROD is a compact reactor which allows to obtain hydrogen by pyrolysis of methane. For this purpose we created a chemical compression reactor.

MEET US

© All Rights Reserved. AL2TEO®

CONTACTS

R&D office, Russia, Novosibirsk, Nikolaev street, 11

UAE, Dubai, Silicon Oasis, SIT Tower, office 1912

UAE, Dubai, Silicon Oasis, SIT Tower, office 1912

Italy, Montecchio Maggiore (VI), Via 2 Giugno 6

China, Chengdu, 中科微电子产业技术西南研究院孵化中心

support@al2teo.com

+971521020256